|

|

|

Tomato Juice Extraction

Tomatoes &

fruits juice extraction -

Cost effective solutions, outstanding quality and reliability

are common for Fenco food processing machines.

Mono & Twin Jet

Pulper finisher for tomatoes and

fruit products

- Pulping, finishing and pressing in one unit

- Vertical design

- -3 section screening in series provides two separate juice

streams

- Special rotors

- Conical / cylindrical screens

- Variable speed

- Quickly removable upper section

- Spray manifolds for each section

- Cooled lubrification system

- Single stage Mono Jet version available (MJ)

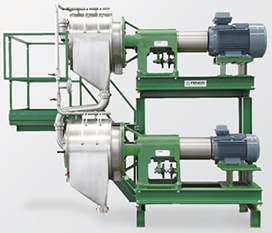

DOUBLE STAGE TURBO EXTRACTORS Mod.

FEX

Each unit consisting of "Pulper and Finisher" placed on the same steel

structure complete with mezzanine for easy access on the upper unit.

Each unit consisting of:

- PULPER

body, fully made of stainless steel AISI 304; mirror polished inside

and glazed outside.

- FINISHER

body, fully made of stainless steel AISI 304; mirror polished inside

and glazed outside.

- Each body includes:

- one horizontal rotor provided with stainless steel AISI 304

rotor,

distance between the screen and the rotor is adjustable without

stopping the machine;

- easy extractable conical screen in stainless steel AISI 304,

- each pulper will have screen with holes diameter 1,5 mm;

- each pulper will have screen with holes diameter 0,8 mm;

- manifold for juice and wastes discharge stainless steel

AISI 304

- header for shaft support directly coupled with the electric

motor by means of a flexible joint;

- one electric motor IP 65 for pulper at 4 poles controlled

by frequency inverter;

- one electric motor IP 65 for finisher at 4 poles;

- Manual wheeler for adjusting of the squeezing degree/action;

- C.I.P. semi-automatic system by steam;

- Control cabinet made of stainless steel AISI 304 provided

with frequency inverter for the speed variations of the finisher.

Technical

data:

- - Max working capacity: 32 - 35 tons/hour

each double stage

- - Rotor dia. Pulper:

400 mm

- - Rotor dia. Finisher:

400 mm

- - Total installed

power: 30 + 15 = 45 KW

Screen changing - dismantling

operation standard procedures for earlier and new turbo extractors

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

Tomato drinkable juice

|

Battery of twin Jet tomato juice

extractors

Battery of double stage tomato uice

extractors

Twin jet tomato juice extractors

Double stages turbo extractor for

tomato juice

Tomato juice turbo extractors

Double stages turbo extractor for

tomato fruit juice, manual distance adjustment between rotor and screen

distance

|